Sign up for our daily edtech news briefing today, free.

I’ve worked on fighter jets for 20 years, so I know how to build things. At Palo Verde High School in Nevada, I teach engineering and recently helped create a manufacturing lab for our students, tapping curriculum from Project Lead the Way and equipment from Intelitek.

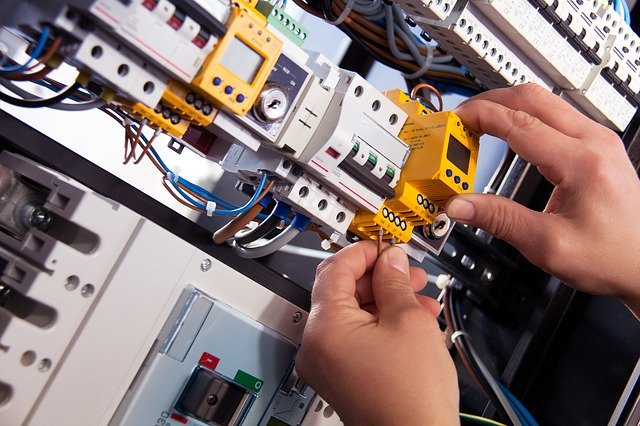

PLTW is a four-year program that teaches students 3D modeling (introductory engineering design); applied physics (principles of engineering); and turning 3D modeling into code that machines can read (computer-integrated manufacturing or CIM). The final course is engineering design where students invent things based on what they’ve learned in the previous three years.

https://www.youtube.com/watch?v=0P6ZG5cirx8]

Workers with technical skills help boost economy

PLTW is designed for college-bound kids and many of my students go on to study engineering at large universities. But students also have the option of going to work right out of high school with the technical skills they are learning in class. For example, we recently received a call from a local company asking if he had any students qualified to run lasers and water jets. The Las Vegas company told me that if we sent trained students, the company would invest in teaching them how to work on lasers and water jets. One of our students is now working part-time for one of these companies for $17.50/hour until he finishes school. Then he’ll work for the company full time. This student now does exactly what I teach kids in this program to do and for good wages.

Here’s another example: Tesla moved its plant to Nevada and manufacturing became popular at just the time we were creating our program. Last December, we met with 11 local CEOs from construction and small manufacturing companies who needed students like ours to fill their staffing needs. Manufacturing is production and production is key to economic growth.

Higher education still matters

Although kids can get a job right out of this program, they will need additional training to find a satisfying career. I remind my kids that this is a great jumpstart, though. If you have skill right out of high school and find work with a good company, the company will send you to a post-secondary school so you can grow vertically in the company. They will pay for that. I’ve talked to business owners and they tell me, “We’ll pay for their education, just find us the kids.”

Automation: The big picture

Creating a manufacturing program provides students with essential technical skills to begin a career, or it can help students gain entry to engineering programs at top universities.

I advise schools to showcase the opportunities for students. If they can see how it works — applying the math and science — they’ll become interested. These engineering skills are useful in other careers besides manufacturing. Automation is an essential part of any manufacturing business. Learning about automation and manufacturing provides good training for many future technical careers.

Stephen Turbie is an engineering instructor at Palo Verde High School in Las Vegas, Nevada.

_____________________________________________________________________________

Like this article? Sign up for our Edtech news briefing to get news like this in your inbox, or check out all of SmartBrief’s education newsletters, covering career and technical education, educational leadership, math education and more.

More from SmartBrief Education:

- Free resources for educators during the coronavirus pandemic

- Distance learning while respecting students’ home lives

- 8 ways to make vocabulary instruction more effective